Lapel pins have become increasingly popular in various sectors, including corporate branding, event memorabilia, and fashion accessories. The art of crafting these pins involves meticulous attention to detail, a deep understanding of materials, and a commitment to quality. This article explores the journey of custom lapel pins from concept to creation, highlighting the skills and techniques used by artisans in this field.

Historical Development

Origins of Lapel Pins

Lapel pins have a rich history dating back centuries, with their origins rooted in ancient civilizations. Initially, these pins served functional purposes, such as fastening clothing or signifying membership in a group or society. Over time, lapel pins evolved into decorative items, often worn to display allegiance, honor achievements, or commemorate special events.

Source:https://mvictors.com/michigan-athletic-association-union-pin-tradition/

Evolution Through the Ages

Throughout history, lapel pins have undergone significant transformations. In the medieval period, knights and nobility wore ornate pins adorned with precious metals and gemstones. The industrial revolution brought about advancements in manufacturing techniques, making lapel pins more accessible to the general public. In the 20th century, lapel pins became popular among military personnel, political campaigns, and social movements, each using these small emblems to convey powerful messages.

Source:https://oldenglishprints.com/pages/history-of-enamel-pins

Influence of Cultural and Historical Events

Cultural and historical events have played a crucial role in shaping the design and significance of lapel pins. For instance, during World War II, soldiers wore pins to represent their units and achievements. In the 1960s and 1970s, lapel pins became symbols of political activism and social change. Today, they continue to evolve, reflecting contemporary trends and societal values.

Source:https://www.amazon.com/Popular-Enamel-Lapel-pins-INVAS-World/dp/B07Q1CJFTX

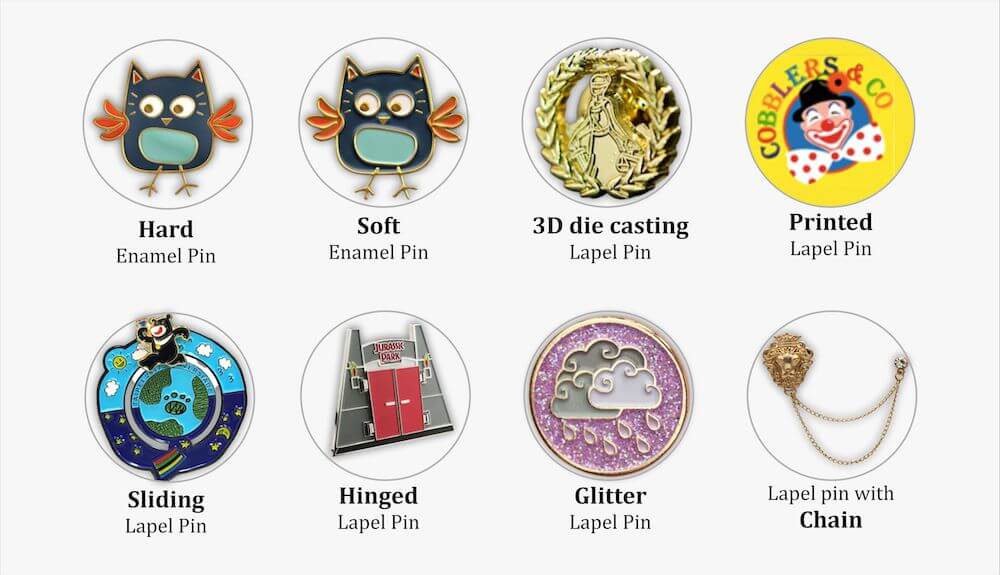

Types of Custom Lapel Pins

Source:https://www.pinsfun.com/types-of-lapel-pins/

Hard Enamel Pins

Hard enamel pins, also known as cloisonné pins, are renowned for their durability and smooth finish. These pins are made by filling recessed areas with enamel and then polishing the surface until it is flush with the metal lines. The result is a high-quality pin with a glossy appearance and vibrant colors.

Source:https://us.pins24.com/en/pins/hard-enamel/

Soft Enamel Pins

Soft enamel pins are characterized by their textured surface, where the enamel sits below the metal lines, creating a raised and recessed effect. These pins are versatile and can incorporate a wide range of colors and finishes, making them popular for various applications, from promotional items to collectibles.

Source:https://www.sunfitworld.com/products/custom-pins

Die Struck Pins

Die struck pins are crafted by stamping a design onto a metal surface without the use of enamel. This technique highlights the metal’s texture and details, resulting in a classic and elegant look. Die struck pins are often used for prestigious awards and commemorative items.

Source:https://wizardpins.com/products/diestruck-pins

Offset Printed Pins

Offset printed pins are ideal for designs that require intricate details and color gradients. This method involves printing the design directly onto the metal surface and then coating it with an epoxy layer for protection. Offset printed pins are perfect for reproducing complex logos, photographs, or artwork.

Source:https://allaboutpins.com/offset-printed-pins

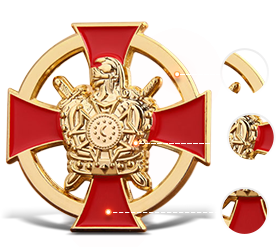

3D or Molded Pins

3D or molded pins offer a three-dimensional representation of a design, adding depth and texture. These pins are created using molds and can be made from various materials, including metal and plastic. They are often used for custom shapes and detailed designs that stand out.

Source:https://www.enamelpins.com/Custom-3d-or-cutout-pins

Materials Used

Types of Metals

The choice of metal significantly impacts the quality and appearance of custom lapel pins. Common metals used include iron, brass, copper, and zinc. Each metal offers distinct properties, such as durability, malleability, and finish. Designers select the appropriate metal based on the pin’s intended use and desired aesthetic.

Source:https://lapelpinsexpress.com/plating-options

Enamel Types and Colors

Enamel is a key component in many custom lapel pins, providing vibrant colors and a smooth finish. There are two main types of enamel: hard enamel and soft enamel. Hard enamel offers a polished, glass-like surface, while soft enamel creates a textured effect. A wide range of colors is available, allowing for intricate and eye-catching designs.

Special Materials

In addition to traditional metals and enamels, designers may incorporate special materials to enhance the pin’s appeal. Glitter, glow-in-the-dark enamel, and translucent finishes add unique elements to the design. These materials are often used to create limited-edition or novelty pins.

Techniques and Methods

Die Striking

Die striking is a fundamental technique in lapel pin production. It involves creating a custom die with the desired design and using it to stamp the design onto a metal sheet. This process produces a raised impression of the design, which is then cut out to form the pin.

Enameling Process

The enameling process involves filling the recessed areas of the pin with enamel. This can be done using either hard or soft enamel. The enamel is carefully applied by hand or machine, ensuring even coverage and vibrant colors. Once the enamel is applied, the pin is baked at high temperatures to cure and harden the enamel.

Plating and Finishing

Plating adds the final touch to custom lapel pins, giving them a polished and professional appearance. Common plating options include gold, silver, nickel, and black nickel. The pins are submerged in a plating

solution, where a thin layer of metal is deposited onto the surface. After plating, the pins undergo additional finishing processes, such as polishing, to achieve a smooth and shiny look.

Cutting and Molding

Cutting and molding are essential techniques for creating the precise shape and details of custom lapel pins. Cutting involves using specialized machines to trim the pin to its exact dimensions. Molding, on the other hand, is used to create three-dimensional designs by pouring molten metal into custom molds.

Customization Options

Color Choices

Custom lapel pins offer a wide range of color options, allowing clients to match their brand or event themes. Designers use color charts and samples to help clients choose the perfect shades for their pins. Custom colors can also be created to meet specific requirements.

Size and Shape Variations

Lapel pins can be customized in various sizes and shapes to suit different needs and preferences. Whether it’s a small, subtle pin or a large, eye-catching design, customization options allow for flexibility in creating unique and memorable pins.

Attachment Options

The type of attachment used for lapel pins can vary based on the pin’s purpose and the wearer’s preference. Common attachment options include butterfly clutches, rubber backs, magnetic backs, and safety pins. Each option offers different levels of security and ease of use.

Special Finishes

Special finishes, such as antique, matte, or glitter, can add an extra layer of uniqueness to custom lapel pins. These finishes enhance the visual appeal and provide additional customization options for creating standout designs.

Environmental Impact

Sustainable Materials

Using sustainable materials in lapel pin production is becoming increasingly important. Eco-friendly metals, such as recycled brass and copper, are popular choices for environmentally conscious clients. These materials reduce the environmental impact and promote sustainable practices.

Eco-Friendly Production Techniques

Eco-friendly production techniques, such as energy-efficient machinery and reduced waste processes, help minimize the environmental footprint of lapel pin manufacturing. Implementing these techniques ensures that the production process is both efficient and environmentally responsible.

Recycling and Waste Management

Effective recycling and waste management practices are essential for minimizing the environmental impact of lapel pin production. This includes recycling scrap metal, properly disposing of hazardous materials, and reducing waste through efficient production methods.

Challenges in Crafting Custom Lapel Pins

Design Limitations

One of the primary challenges in crafting custom lapel pins is adhering to design limitations. Certain designs may be too complex or detailed to replicate accurately in a small pin. Designers must balance creativity with practical considerations to achieve the desired outcome.

Material Constraints

Material constraints can also pose challenges. Some materials may not be suitable for specific designs or finishes, limiting the options available to clients. Finding alternative materials that meet both aesthetic and functional requirements is essential.

Production Hurdles

Production hurdles, such as machine malfunctions or supply chain disruptions, can impact the timeline and quality of lapel pins. Effective project management and contingency planning are crucial for addressing these challenges and ensuring smooth production.

Client-Specific Challenges

Each client has unique requirements and preferences, which can present challenges in the design and production process. Clear communication and collaboration with clients help address their specific needs and deliver a product that meets their expectations.

Tips and Advice for Aspiring Pin Makers

Aspiring pin makers can benefit from practical tips and advice from seasoned professionals. Key advice includes focusing on mastering the basics, continually learning new techniques, and maintaining a strong commitment to quality. Building a portfolio and seeking feedback are also essential steps for growth.

Conclusion

The art of crafting custom lapel pins is a fascinating blend of creativity, precision, and technical skill. From the initial concept to the final product, each step in the process requires careful attention to detail and a deep understanding of materials and techniques. Custom lapel pins serve various purposes, from corporate branding and event memorabilia to fashion accessories and recognition awards.

Design your custom lapel pins with Blythe. Enjoy free design consultations, personalized service, fast turnaround, and affordable rates. Contact us now to start creating your distinctive lapel pins!